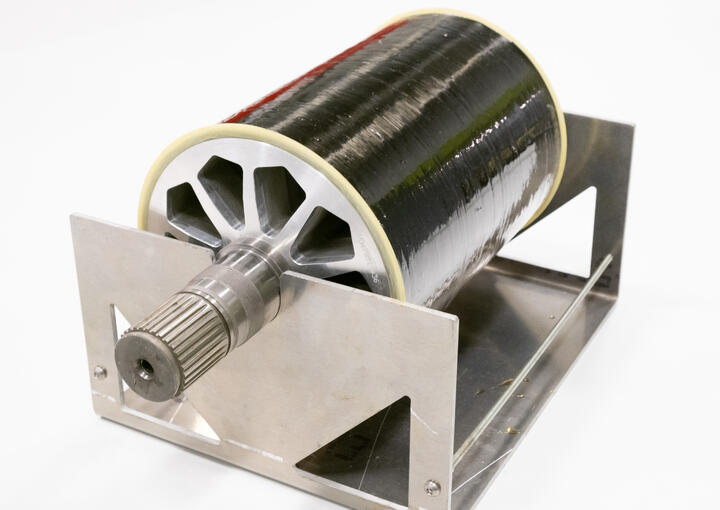

New processes have been devised and technology de-risked by the AMRC to help increase electric motor production rates for the UK’s largest supplier of electric drive systems – with an ambition of transitioning from 60 to 5,000 traction motors per year.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) formed part of a consortium of experts tasked by Magtec, based in Rotherham, to support the business need for new ways to reduce bottlenecks within its production processes to enable an increase in the number of electric motors it could make per year.

AMRC engineers with expertise in composites and integrated manufacturing supported Magtec by successfully creating factory simulations to optimise vital decisions prior to implementing changes to production and making investment decisions, helped them adopt a towpreg winding technique, reducing set-up time and increasing throughput, as well as providing ideas and advice on alternative lamination technologies it could use in the future as the business grows.